Iimveliso

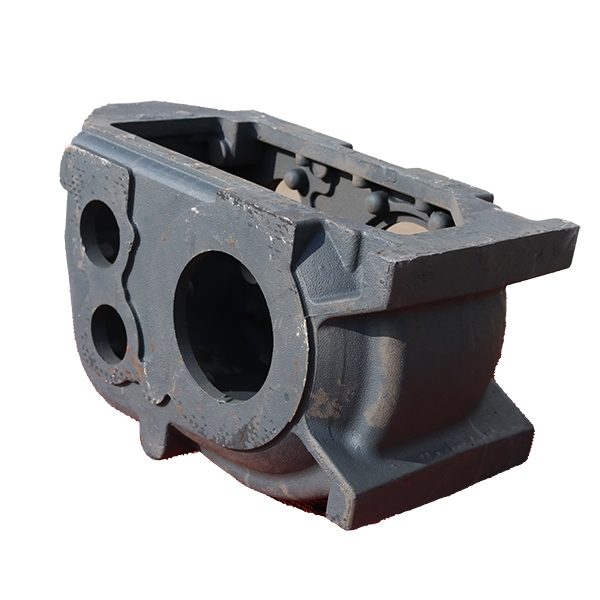

I-604.39.295 yokudibanisa ityhubhu

Inqaku lemveliso

I-foam ilahlekile Ngokukhawulezisa ukuphikisana (ukomelezwa), egudileyo kunye nokuphefumla) kwaye womiswe, kungcwatywe kwi-quartz eyomileyo kwaye iphantsi kwemodeli yomomileyo. Intsimbi etyhidiweyo ithululwe kwibhokisi yesanti esenziwe phantsi koxinzelelo olubi, ukuze imodeli yezinto zePolymer ishushu kwaye ivalwe, emva koko ikhutshiwe. Indlela entsha yokuphosa esebenzisa isinyithi yolwelo ukuze ithathe indawo yokuphosa ixesha elinye lokuphosa emva kokupholisa kunye nokuqina ukuvelisa izikhumbuzo. I-foam elahlekileyo ineempawu ezilandelayo: 1. IIMPENDULO ZEMISEBENZI EYINIYO NEENCWADANA ZEMALI; 2. Izixhobo azipheleli kwaye zilungele bonke ubungakanani; 3. Ukuchaneka okuphezulu, indawo egudileyo, ukucoca okungaphantsi, kunye nematshini ephantsi; I-4. Iziphene zangaphakathi zincitshiswa kakhulu kwaye ulwakhiwo lokuphosa luphuculwe. Xina; 5. Inokufumana umda omkhulu kunye nobuninzi; 6. Ilungele ukuvelisa ubuninzi bokuphosa kwalowo; 7. Ilungele ukusebenza lencwadi kunye nokuvelisa umgca wokusebenza ngokuzenzekelayo kunye nokulawulwa kokusebenza; I-8. Imo yemveliso yecandelo lemveliso ifezekisa iimfuno zoKhuselo lweNdalo kwiParameter. ; 9. Kungayiphucula kakhulu imeko yokusebenza kunye neemeko zemveliso zomgca wemveliso yokuphosa, ukunciphisa ubungakanani bomsebenzi, kunye nokunciphisa ukusetyenziswa kwamandla.

Ingcaciso yeMveliso

Uyilo lubhetyebhetye kwaye lubonelela ngenkululeko eyaneleyo yokuphosa uyilo lolwakhiwo. Ukuphoxeka kakhulu kunokuphoswa kwindibaniselwano yokubumba kwe-foam.

Ukunciphisa imali yotyalo-mali kunye neendleko zokuvelisa, ukunciphisa ubunzima bokuphosa izithuba, kwaye ube nezibonelelo zoomatshini abancinci. (1) Ubungakanani be-batch

Akukho sigqubuthelo sentlabathi ekuphoseni intlabathi, ke akuyi kubakho bubukhulu ongalinganiyo wodonga olungafaniyo nobungakanani bentlabathi engalunganga yesanti okanye isikhundla esichanekileyo kwiSanti seSiko.

I-Ascancess ichaphazelekile. I-Foam ye-Foam iphosa i-foam yenkqubo entsha yenkqubo ephantse yaphantse yangaphantsi kwaye ichanekile. Le nkqubo ayifuni ukuba ithathe, indawo ethengisayo, kwaye akukho santi, ke iingcinga azinanto, iimpazamo ezibangelwa yingqungquthela ye-Core encitshisiweyo. Ubungqingqwa bokuthintela okungaphezulu kunokufikelela kwiRa3.2 ukuya kwi-12.5μm; Ukuchaneka kweNgqiqo kwezokuNgqineka Kungafikelela kwi-CT7 ukuya kwi-9; Isibonelelo somatshini siyi-1.5 ukuya kwi-2mm uninzi, olunokunciphisa kakhulu indleko zomakhi. Xa kuthelekiswa nendlela yesanti yemveli, inokuncitshiswa ngama-40% ukuya kwi-50% yexesha lokwakha.

Ukuveliswa kwemveliso, akukho machiza emichiza kwiSanti yokuBuda, iiplasitiki ze-foam zinobuhlobo kwiqondo lobushushu eliphantsi, kwaye izinga lokurisayikilisha lentlabathi endala ingaphezulu kwe-95%.

Ngaba ufuna ukuxoxa ngento esinokuyenza?

Jonga apho izisombululo zethu zingakuthatha khona.